As model railroaders, we routinely make concessions to scale. Either overscale details (like handrails) or loss of detail altogether. Thicker wheels. Larger flanges. And more. But for N scale, Arnold (aka Rapido) couplers should not be one of them. (At least I don’t think so.)

There are a lot of alternatives out there. Kadee (now MTL,) Accumate, McHenry, and more are options.

In my case, modeling Japanese railroads, operations doesn’t involve a lot of switching, so the per-unit expense of fully operable kuckle couplers isn’t warranted for me.

Conveniently, Kato itself makes a set of couplers (11-702, seemingly named “buckeyes") that function reasonably well. They couple on straights and curves, they stay coupled under a variety of circumstances, and they uncouple—albeit manually—without too much effort. And they look fairly reasonable, too.

Oh, and a pack of 20 is a few bucks.

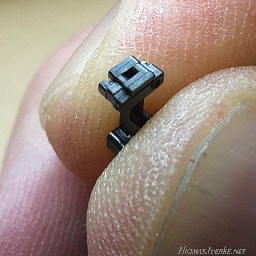

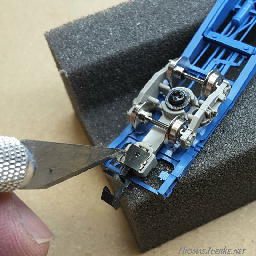

The rub: some assembly is required.

Given that there hasn’t been much info about these (at least not in English, so far as I can tell) let me share my experiences.

Basic facts

- Most Kato JR locomotives come with Arnold couplers, but have an alternate pair of couplers stashed away in one of the little plastic bags of accessories. Those couple just fine with the 11-702's. Given that that they’re designed for that specific locomotive, odds are that they’ll fit much better than the more generic buckeyes, so use those.

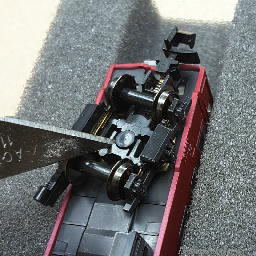

- Kato freight (and some passenger) rolling stock comes with Arnolds. It is for these that the buckeyes are designed. Replacement is typically fairly easy. (See below.)

- Other Kato passenger rolling stock—DMUs, EMUs, and Shinkansen, for instance—have special, proprietary couplers, typically emulating the appearance of Scharfenberg couplers. You neither need nor want to replace those, since typically those trains are run as units, where you’re not likely to uncouple them except to put them back into their box.

- So far, I’ve been able to replace the Arnolds on Tomix rolling stock, too. The coupler fits into the coupler box reasonably well, and fortunately they’re at the same height as Kato’s.

- The jury is still out on Tomix locomotives, though I’ve been able to convert one or two, with satisfactory results. Every locomotive is slightly different, typically needing a specialized (Arnold) coupler to fit its coupler box, and I’ve actually filed a pair of buckeyes to fit the shape.

- Most Arnold couplers—in Kato and Tomix alike—are set with a tiny metal spring to keep it returning to a center position. With the buckeyes, this doesn’t seem necessary; they seem to return to center on their own, while still having a reasonable amount of play. But if your a stickler (and incredibly patient) you can keep the spring in place while doing the replacement. (If I feel particularly masochistic some day in the distant future, I may go back and reinsert the springs in some of my rolling stock, but I haven’t felt the need to subject myself to that level of abuse just yet.

Oh, and one more thing: using these seems to take about a scale foot (that’s roughly 30 scale centimeters, or 2mm actual) out of the space between cars. That’s between 20-25% of the gap, and fairly noticeable in most cases. (Naturally, that may be a concern around tighter corners, so caveat emptor.)

Comparison

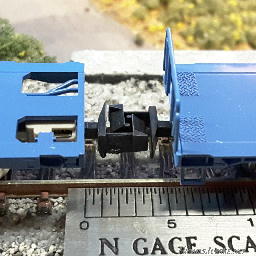

Here we see a comparison of Arnold couplers and the Kato buckeyes. In the upper pair, the two Kato Series 50 passenger cars are visibly closer together. A scale rule below shows the gap to be roughly 5 scale feet (about 1.5 scale meters) for the Arnolds, and significantly less (closer to 4 feet or around 1.2 meters) for the buckeyes. A worthwhile improvement, I think. (And despite the less-than-prototypical appearance, within the shadows between the car, they look realistic enough to pass.)

| Arnold/Rapido | Kato 11-702 Buckeye |

|  |

| Above: Series 50 “Red Train” Passenger cars. Below: JR KoKi container cars | |

|  |

In the second comparison, two Tomix KoKi container cars are coupled, and again, the distance between the two reduces by about one scale foot (.3 meters.) It’s not as obvious here, because the lower profile, but the scale rule suggests it is so.

Assessment

Here we round up the pro’s and the con’s. For me, the pros have it, but your mileage may vary, so look at this and see what you think.

| Pro | Con |

| ⊕ Flexibility: They can be installed on a wide range of Kato, Tomix, and possibly other rolling stock, to replace the Arnold/Rapido couplers already there. ⊕ Easy to Replace: barring the assembly, once you have a bunch of these put together, swapping out the Arnolds is usually quite fast. ⊕ Appearance: They look much better than the Arnolds they replace. ⊕ Functionality: They work at least as well, too, at least in terms of being able to couple as well as pull cars over track and around curves. ⊕ Smaller Gap: They short the gap between cars by at least a scale foot. ⊕ Cost Effective: In comparison to other couplers, they are very inexpensive. | ⊖ Completely manual: Arnolds have facilities for automatic uncoupling, as do Kadee’s et al. ⊖ Proprietary: one of several different styles of coupler which generally don’t interoperate (at least not very well...) ⊖ Assembly required: not recommended for those with “fat fingers” or failing eyesight. ⊖ Not prototypical: While nothing in the N scale pantheon of knuckle couplers takes the cake, these are not even in the running; they look less unprototypical than Arnolds, but that’s about it. ⊖ May impact minimal turn radius by bringing coupled cars closer together. |

| Verdict | |

| If you’re not concerned with automatic coupling operation (or have large blocks of “unit” rolling stock) these are reasonable alternatives to Arnolds, being neither so garishly unprototypical as they are, nor as expensive—car for car—as other knuckle couplers. If operations (or more prototypical appearance) is important for you, or you really don’t like fussing with tiny bits of plastic, then you may want to take a pass. | |

While the conversion is an ongoing process, so far I’ve got a fairly significant chunk of my rolling stock using buckeyes, and they work just fine.

Generate a QR code link to this page

Generate a QR code link to this page